Setting up an electrical wiring diagram can be confusing, especially if you run into terms like load centers and panelboards. So what’s the difference between them?

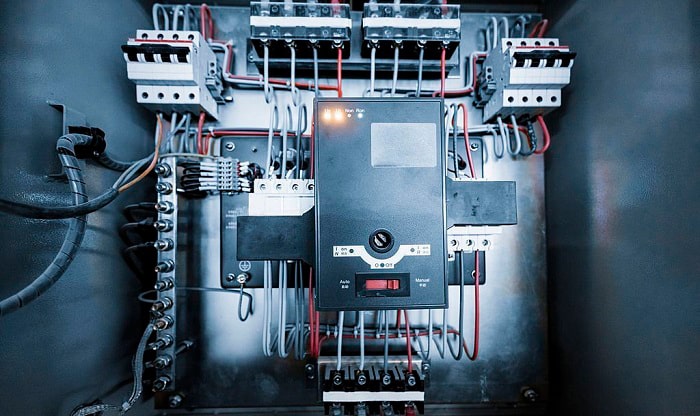

Generally, there are no significant differences between a load center vs panelboard. Both electrical enclosures house circuit breakers for the facility or residence.

Take note that some slight dissimilarities may exist between the two terms based on specific models. So continue reading to gain additional insight into load centers and panelboards.

Table of Contents

What is It?

The terms load center and electric panelboard are interchangeable. They refer to a system that allows safe control and distribution of electricity throughout the property.

Other terms that you can use to indicate a load center are:

- Switchboard

- Switchgear

- Motor control center

Pros And Cons

Below are some advantages and shortcomings of a panelboard or load center panel.

- Contains breakers, therefore providing protection against electrical faults such as overcurrent.

- Available both as main breaker and lug panels, the latter of which allows users to add more circuits and distribute power in locations far from the main load center.

- Smart load centers enable the remote monitoring and control of a home’s electrical system through apps.

- Load centers cannot house all breaker types, so if you’re using one brand of panel, you may have to use breakers from that same company.

- Is only accessible from the front; no rear or side opening.

Aside from the above points, you may find differences when comparing brands of load centers as well.

For example, an Eaton panel board can have large dimensions and often have more expensive prices than other load centers made from other brands. Still, many users found Eaton’s models to be quite durable and relatively easy to install.

Differences

The differences between the terms panelboard vs load center are fairly few while looking at them from a general standpoint. Both labels indicate a protective housing for circuit breakers.

But panel boards electrical enclosure may also specifically indicate a breaker box’s internals. In comparison, a load center can be a trade name.

Plus, you may find brands preferring one term over another in naming their products. For example, Scheneider offers a QO panelboard and an NQ load center electrical box at the same time.

QO panelboards are better options for residential use, particularly as a lighting panel board. However, an NQ load center might be the better choice if you’re going to house circuit breakers for commercial or industrial facilities.

So you might be able to use an NQ load center in forklift. But it may not be possible to use a QO panelboard for the same application.

Switchboard vs Panelboard

As with other load center names, the differences between panelboard vs switchboard are fairly scarce.

Switchboards are often the typical choice for industrial establishments. These panelboards generally house circuit breakers that can manage and supply electricity for machines with high-voltage demands.

Panelboards are only accessible from the front (as mentioned above), but switchboards allow rear access as well.

Moreover, the latter can handle higher fault currents.

Switchgear vs Panelboard

Switchgears and switchboards are often interchangeable terms like load centers and panelboards. But switchgears are the largest of all these fixtures. They can also handle more short circuit cycles (30 compared to panelboards’ 3).

Frequently Asked Questions

Panelboard And Distribution Board: What Is The Difference?

The definition of the term panelboard is roughly the same as the distribution board.

Electrical panel board specifications dictate that they’re rated for up to 1,200 amps and are mounted in cabinets or on walls.

Does A Load Center Have A Main Breaker?

Electrical load centers usually have main breakers located at the top of the inside of the enclosure. It functions by controlling all branch circuit breakers within the panel board.

Take note that the main panel board circuit breaker won’t turn off the power from the utility. Instead, it only disconnects the branch circuit breakers from the connected electrical service lines.

What Are The Types Of Panel Boards?

Generally, the two main types of electrical panel boards are appliance and distribution. However, you can find six other kinds of panel boards under these two main classifications. These varieties are:

- Type 1: Usually meant for indoor use.

- Type 3R: Can fit indoor or outdoor use but offers a similar if not the same protection as a Type 1 power panel board.

- Type 4: Generally used to protect individuals from electrical hazards.

- Type 4X: A tougher model than Type 4 as it adds corrosion resistance to its list of features.

- Type 5: Typically intended for indoor use and offers protection from dangerous components.

- Type 12: Similar to the Type 5 enclosure; protects internal components from dust and other small debris.

Conclusion

By now, you should have a better idea of the differences and similarities between a load center vs panelboard. Remember, you can interchange these terms.

However, it’s still ideal to be aware of the potential dissimilarities among the different electrical enclosure models. For instance, don’t use certain panelboards for a commercial electrical setup.

Understanding the underlying particulars of load centers can help you stay out of trouble during and after the installation of these systems.

I am Edwin Jones, in charge of designing content for Galvinpower. I aspire to use my experiences in marketing to create reliable and necessary information to help our readers. It has been fun to work with Andrew and apply his incredible knowledge to our content.