If you want to know how to size a circuit breaker for a motor properly and safely, you should, first and foremost, do what the NEC recommends, particularly in various sections of Article 430. You can also get the information you need from the motor’s nameplate, which can be searched online if it happens to be illegible.

My guide will be mostly based on how you’re supposed to follow these sizing recommendations with the motor’s horsepower, type, voltage, and size in mind.

Table of Contents

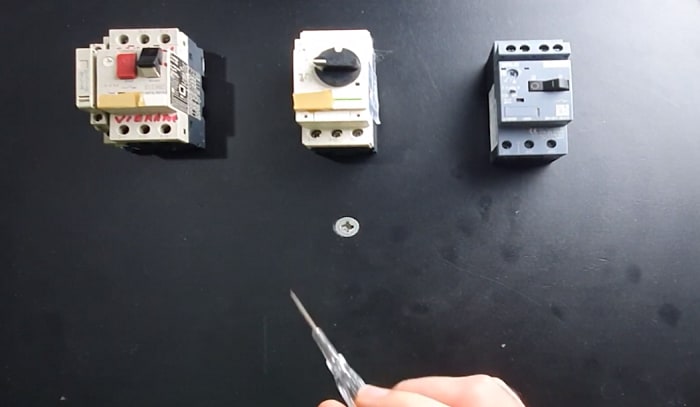

Tools You’ll Need for Proper Sizing

A copy of the National Electric Code

If you haven’t got one readily available, you can try getting free access to it via the NFPA. Otherwise, you may need to subscribe. You will need a copy of the Code since you’ll be referring to the tables containing the necessary information to arrive at the right motor breaker size for your particular application.

Even better if your motor already has the information you need through its nameplate. I’ll explain why in the first part of the following section. Lastly, another step you can do, especially if you haven’t got a copy of the NEC, is to do a manual calculation.

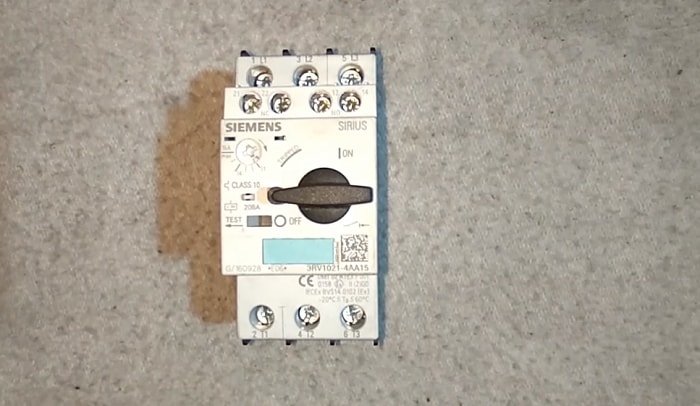

For convenience, I recommend the nameplate method since the exact amperage will be given to you. You can confirm this information by referring to the tables provided in Articles 430.32 and 430.52 of the NEC. However, I’m also not completely ruling out performing manual calculations because of the reasons I’ve outlined below.

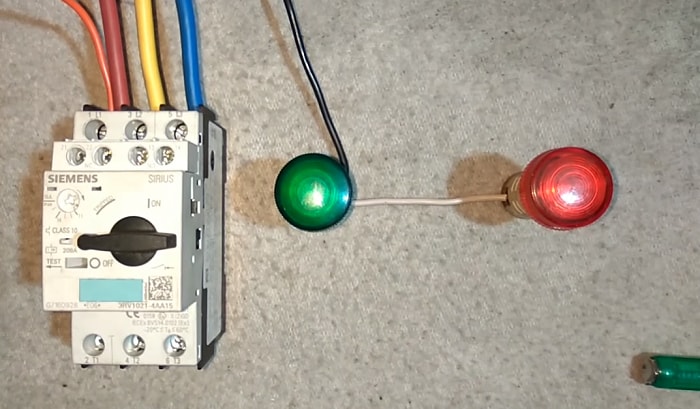

How to Size Breakers Properly for Various Types of Motors

All in all, sizing a breaker for a motor can be summed up by the following pointers and steps:

- Know the exact horsepower of the motor by looking at the information found on its plate. If the rated currents for both 240V and 480V are already available, assuming you’re from the US, then that should give you the exact size you need as represented in amps.

- If you only know the horsepower and voltage, determine the type of the motor, whether it’s continuous or non-continuous, and whether it requires 125% current protection by looking at the table provided in Article 430.32 of the National Electric Code.

- You’ll also need short circuit protection, and for this, you’ll need to refer to the table on Article 430.52. This one is based on the total load and the size of the motor.

I don’t go beyond these three points whenever I’m breaker sizing for motors. Sure, you’ll have variations when it comes to motor and circuit breaker types, but these three steps never fail to help me get the exact sizing information I need.

Incidentally, if you reside outside the US or want a motor circuit breaker sizing calculator, I recommend you to try out the one provided by Electrical Technology. It beats any custom motor circuit breaker sizing chart I’ve come across in the past. Here’s how you can use it:

- Simply set what you want to calculate. In this case, it’s obviously the breaker size, so choose that.

- Afterward, set the country and the corresponding voltage you want to check. No need to set the breaker amps and wattage. You’ll get the minimum breaker size and recommended breaker size in the bottom section. Easy as pie, right?

- If you’re having doubts or want to verify the result, just refer to the tables I mentioned.

But, what if you haven’t got a copy of the Code on hand or you only remember portions of it? Or let’s say you find yourself without Internet access suddenly. It’s instances like these that make a case for knowing how to do a manual calculation when trying to size a breaker for a motor.

Another obvious advantage of having this skill is that you won’t have to whip out a copy of the Code or use a breaker size for a motor calculator every time you need this specific information. It may also come in handy if you’re using a different type of circuit breaker, like, for example, an inverse time breaker, which has an overall capacity of 250% of the entire load.

Related: Calculating Breaker Size for a 12V Trolling Motor.

How to Manually Calculate the Correct Circuit Breaker Size for a Motor

There are plenty of factors that will have to be taken into consideration when doing manual calculations. These include:

- The motor’s horsepower and voltage

- Whether the motor is a single-phase or three-phase supply

- Power factor

- Efficiency

- Type of circuit breaker used

1. Begin by calculating the pullout current.

You’ll need a specific formula for this. Let’s say the motor’s horsepower is 25. Its voltage is 220V, while the power factor is 0.8 with an efficiency of 90%. With these values in mind, we’ll arrive at the following equation:

I = (25 x 746) / (√3 x 220 x 0.8 x 0.9)

The total pullout current is 67.98 amperes.

2. Get the exact ampere rating relative to the type of circuit breaker you’re using.

Assuming you’re using an inverse time circuit breaker, you will have to follow the following formula:

I = 67.98 amps x 250%

Therefore, the total value in amps is 169.95. Admittedly, you’ll also need to refer to the Code at this point, assuming you haven’t memorized the table in section 240.6, which expounds on the ampere ratings relevant to inverse time circuit breakers.

Since we got close to a 170A rating in our calculation, we’ll then need to use a 175A breaker since Code states that it should always be slightly higher than the former.

Again, this underscores the importance of the type of circuit breaker you’re using because it can drastically change the size that you’ll need for your specific requirements.

Other Pointers to Keep in Mind

- Remember that your particular equipment’s motor may drastically affect the final circuit breaker size as well as its applicable type. For example, article 440.22 of the NEC actually states that for most air-conditioners, you can’t use breakers that exceed 175% of the motor’s rated-load current.

- The total starting current of the motor also determines whether the percentage of the rated load current should be increased. For ACs with high starting currents, the total load current can be increased to 225%.

If you want to learn how to manually calculate load currents as well, I suggest you watch this video tutorial:

Conclusion

Did you find my guide on how to size a circuit breaker for a motor useful? I’d appreciate it if you’d share your thoughts about this subject in the comments section below. If you liked it, it will also make my day if you share this article to others whom you think will find it valuable.

Remember that there’s no beating what the NEC suggests when it comes to motor breaker sizing. It’s about maintaining the efficacy of a particular electrical system and simultaneously guaranteeing that the entire setup is 100% safe. More or less, the information embedded on the nameplates adheres to it as well.

I am Edwin Jones, in charge of designing content for Galvinpower. I aspire to use my experiences in marketing to create reliable and necessary information to help our readers. It has been fun to work with Andrew and apply his incredible knowledge to our content.