You shouldn’t struggle too much in figuring out what size breaker for a well pump, if its manufacturer provided the specific breaker size recommendations via its manual. Double-check the document first and compare it with Code requirements.

Follow the pump manufacturers’ suggestions over anything else because their own well pump amp draw chart and wire sizing usually account for everything: Code recommendations, distance, possible voltage drop, etc.

Read on for some examples and know the safest steps to take.

Table of Contents

Why It’s Ideal to Stick to Manufacturer Requirements

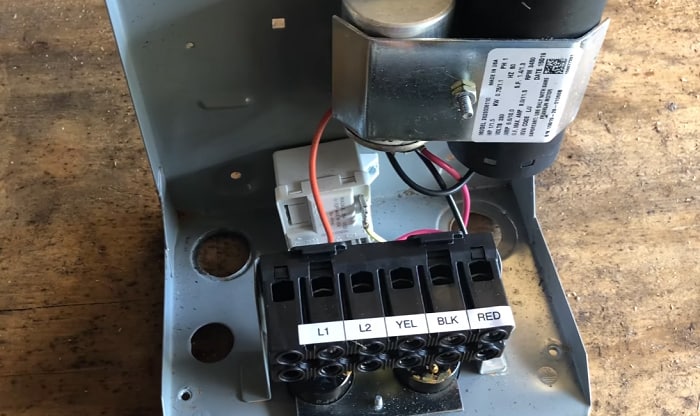

Well pumps, especially submersible pumps, are not your standard motors and often require specialized overload protection. Just ask a lot of well pump installers in your area, and they’ll likely say they consult manuals such as this one created by Franklin.

It provides detailed instructions not only on breaker sizing and wire sizing but also considers distance, temperature, connection type (whether it’s single-phase or three-phase), starting amperage, and voltage drop. Even if we compare these tables to the one recommended by the NEC, you’ll see that they don’t really depart that much and even make it clear that they use its guidelines as a reference.

Here’s a Sample Scenario

Let’s assume you use a 1.5 HP pump with a single-phase motor. Based on Table 14 in the Franklin manual and since you’re likely asking about the breaker size for the 230v well pump, you’ll need to use a 30 amp circuit breaker for it, not considering the distance. On the other hand, a 3/4 hp pump with the same motor type and voltage needs a 20 amp breaker.

If you refer to Table 11 of the same manual that gives the maximum length of wire you can use to keep voltage drop under 5%, you’ll either need to use a 14 AWG copper wire or a 12 gauge one if your distance is either 190 or 310 feet, respectively.

Obviously, wire size should always be in sync with breaker size, and the Code usually doesn’t provide detailed breakdowns of these, unlike the tables found in these manuals. This underlines their value and why some installers make a beeline for them instead of NEC tables for motor amperage and wire sizes.

More importantly, it also accounts for the starting amperages of the pumps, which are usually high. For example, a 2 HP 230v single-phase pump may surge between 50 to 60 amps. Even if it lasts for only a few seconds, your breaker will still need to be able to handle that.

If you’re going to limit your references to passages in the Code, it’s still relatively safe, though, as proven by the next section.

What If The Manufacturer supplies no Clear Information?

Then always make sure that you size a breaker according to Code. Code rules are safe because they actually recommend the maximum, safest size you can use, meaning you can still settle for a smaller breaker without necessarily veering off the official guidelines.

If you’re not sure that you’re doing it properly, then just consult an inspector. In my experience, they always know how to provide accurate well pump electrical requirements while making sure your setup is perfectly Code-compliant.

Usually, residential well pumps have horsepowers that range between ½ HP to 2 HP. According to Code, for 1 HP well pump that’s 230V and single-phase, you may need to use a 25 amp breaker, for example.

But it’s rarely that simple. Well pump breaker size tends to be more range based on my experience installing well pumps.

These are the most important passages in the Code that are pivotal for determining the correct size circuit breaker with regard to well pump amperage. If you have a copy of the National Electric Code, it’s worth checking them out to see for yourself.

- 6(A)(1) makes it clear that you shouldn’t rely on the nameplate value but on the recommendations given in section 430.248, especially if the pump runs on a common single-phase motor.

- 52(C)(1) states that you should opt for the next breaker size if the total amp’s value does not correspond to the ones stated in section 430.52.

- That same section (430.52) provides a passage that underscores that a basic circuit breaker should not exceed 250% of the values shown in 430.248.

These facts prove that the Code recommends maximum size requirements, instead of minimum. This also proves that slight deviations from recommended values are fine as long as you remain compliant with these specific passages.

How to Size a Circuit Breaker for a Pump?

Let’s start with this specific example. How many amps does a 3HP 230v single-phase well pump motor have? 17 amps.

Based on the 250% allowance said above, we’ll arrive at the following formula to get the maximum, safest breaker size for that specific pump:

17 x 2.5 = 42.5 amps

Typically, there are no breakers with that specific size. So we go to the next higher standard size, which is 45 amps.

Does that mean that you should limit yourself to that? As most inspectors will say, not really. They’ll likely size a smaller breaker that will still manage to start the pump’s motor.

In this case, if a 30-amp breaker can handle it, then it’s still perfectly code-compliant. The same goes for 35, 40, or 45-amp ones. However, anything beyond that is no longer technically legal.

Take note that these values don’t consider other factors like wire size and distance, like the ones expounded on above.

Why is It Important to Choose the Correct Size Breaker for a Well Pump?

Submersible well pumps typically have high currents required to start properly. Obviously, your breaker and its corresponding wire conductor should be able to handle that or you risk the possibility of a fire.

Secondly, the pump won’t run optimally and may end up frequently tripping the breaker. Moreover, deep well pumps need to consider longer distances. There are a lot more variables, in short, compared to other gadgets and appliances.

Conclusion

So, again, to know what size breaker for a well pump, don’t depart from the instruction manual as much as possible, especially if the manufacturer already provides detailed information about it. If there are none, make your calculations based on Code rules—all the better if you have time to compare the two and confirm your findings.

If you’re still having doubts, don’t hesitate to ask for technical assistance from the brand you bought the well pump from or a certified inspector or electrician.

Read next:

I am Andrew Wright. With 8 years of experience designing, installing, and maintaining electrical power systems. I love my job, and I have always wanted to offer others the necessary help so they can take care of their houses.