A 150-amp main panel is commonly used as the primary electrical service for residential and small commercial buildings. This capacity is generally adequate to meet the power demands of a typical household or small-scale commercial operation.

However, determining what size wire for 150 amp service is crucial. While 1/0 AWG is often recommended for this application, it’s important to consider various factors influencing the ideal wire size. Let’s explore this topic in more detail below.

Table of Contents

- What Size Wire Do I Need for a 150 Amp Service?

- Wire Size Calculation

- NEC Requirements for Wire Size

- Factors Affecting Wire Size Selection

- The Impact of Wire Size Material

- Safety Considerations and Best Practices When Using 150 Amp Service

- Common Issues of 150 Amp Service and Troubleshooting Guide

- Frequently Asked Questions

- Conclusion

What Size Wire Do I Need for a 150 Amp Service?

A 150-amp service refers to an electrical system that can handle a maximum continuous load of 150 amps. If you were asking, “Is 150 amp service enough for a regular residential household?”, the answer is yes. This will allow you to use common appliances running simultaneously without a problem.

However, a proper size wire should be used if you want to install a 150 amp service in your electrical system. Here is a chart containing the usual minimum size wire you can use for your application, including the ground wire size.

| Electrical Wire Connections | Minimum Recommended Wire Size for 150 Amp Panel | |

| Copper Wire | Alum or CCA | |

| Hot | 1 AWG | 2 AWG |

| Neutral | 1 AWG | 2 AWG |

| Ground | 6 AWG | 4 AWG |

Wire Size Calculation

Knowing the minimum recommended service wire size for commercial or residential applications should be sufficient in most cases. However, certain situations may require more specific wire size when installing 150-amp service.

As a result, a proper calculation should be done considering various factors such as type of application, system voltage, length of wire, and type of conductor. The formula used to calculate the appropriate wire size for a given amperage and voltage drop is as follows:

\[ \text{{CM}} = \frac{{2 \times \text{{wire length}} \times K \times I}}{{\text{{Voltage Drop}}}} \]

Where:

- K represents a constant value depending on the wire conductor (for copper, K is typically 12.9 and 21.2 for alum)

- I is the maximum continuous current (amperage)

- Voltage drop (3% voltage drop of 240v is 7.2v.)

For example, let’s consider you want to install a 150-amp service with a 240v power supply 100 feet away, using a copper wire.

\[CM = \frac{{2 \times 100 \, \text{ft} \times 12.9 \, \Omega \times 150 \, \text{amps}}}{{7.2 \, \text{V}}} = 53,750\]

Then, you can now determine the AWG by referring to a CM to AWG conversion wire size chart. You will see that 53,750 CM is equivalent to 2 AWG. Therefore, it is the recommended wire for the application.

Tips: An online calculator is also helpful in determining the recommended wire size specifically for your application.

Additionally, here is a 150 Amp Breaker Wire Size table at Different Voltage Drop (Copper) that can be used as your reference.

| Wire Length | 3% Voltage Drop | 5% Voltage Drop | 10% Voltage Drop | |||

| 120v | 240v | 120v | 240v | 120v | 240v | |

| Less than 50 ft. | 2 AWG | 4 AWG | 4 AWG | 8 AWG | 8 AWG | 10 AWG |

| 100 ft. | 2/0 AWG | 2 AWG | 2 AWG | 4 AWG | 4 AWG | 8 AWG |

| 150 ft. | 3/0 AWG | 1 AWG | 1/0 AWG | 3 AWG | 3 AWG | 6 AWG |

| 200 ft. | 250 kcmil | 2/0 AWG | 2/0 AWG | 2 AWG | 2 AWG | 4 AWG |

NEC Requirements for Wire Size

The National Electrical Code (NEC) provides guidelines for wire sizing to ensure safe and efficient electrical installations. The NEC sets limits on the allowable voltage drop for different applications.

For branch circuits, a maximum voltage drop of 3% is typically recommended. Moreover, the maximum voltage drop allowed for sub panel applications is 5%. Lastly, a maximum voltage drop of 10% is often acceptable for general appliances and lighting circuits.

Factors Affecting Wire Size Selection

1. Wire length

The length of the wire run influences its resistance and voltage drop. Longer wire runs have higher resistance and can result in increased voltage drop. To minimize voltage drop, larger wire sizes are often necessary for longer runs.

2. Sustained current load

The size of the wire should be selected based on the amount of current that the wire needs to carry. Matching the anticipated maximum current draw of the circuit or equipment limits the risk of overheating or voltage drops.

3. Wire material

Different wire materials have different resistivities, affecting their ampacity and voltage drop characteristics.

- Ampacity: Ampacity refers to the maximum capacity of a wire. A wire must operate within its ampacity cap to prevent exceeding its temperature rating.

- Voltage Drop: Voltage drop happens when a current flows through a wire decreases due to its resistance. Voltage drop can affect the performance of electrical appliances.

The wire size should be selected to minimize voltage drop and maximize capacity within acceptable limits. Copper is commonly used for its high conductivity, while alum is also used but typically requires a larger wire size due to its lower conductivity.

4. Temperature rating of wire

The temperature rating is an important consideration. Higher temperatures can affect the wire’s ampacity and safety.

Some wire types have lower ampacity at higher temperatures, while others are designed to withstand elevated temperatures. The NEC specifies temperature ratings for different wire types, and the selected wire size should meet or exceed the required temperature rating.

The ambient temperature should be considered when installing the wire. High ambient temperatures can mitigate the temperature rating of the wire, which impacts its ampacity.

The Impact of Wire Size Material

Different wire materials have their own set of benefits and drawbacks. Let’s go over the advantages and disadvantages of each:

- Copper Wire

Copper is the most commonly used wire conductor for residential electrical systems. Some of its advantages are excellent conductivity, good corrosion resistance, high tensile strength, and low electrical resistance.

However, it usually comes at a higher cost and heavier weight than other types of wire.

- Aluminum Wire

Alum is now becoming more popular for electrical wiring installation. This is because it comes at a lower cost and lighter weight than copper wiring.

However, using this type of wire usually results in a higher resistance, requires larger wire than recommended size, and is not corrosion-resistant.

- Copper-Clad Alum (CCA) Wire

Another type of wire used in electrical wiring is the CCA wire. It is an upgraded version of aluminum wire. Even though it is more effective than alum wire, it is still less effective than copper.

Safety Considerations and Best Practices When Using 150 Amp Service

When it comes to wire installation, ensuring safety of wire is crucial for properly functioning electrical systems and preventing potential hazards.

Here are some safety practices to follow when choosing and installing wires in a 150 amp circuit:

- Maintain proper wire insulation and protection. High ambient temperature and inappropriate overcurrent protection devices can damage the wire. Install circuit breakers or fuses to prevent excessive current flow and protect the circuit.

- Carefully plan and lay out the project before starting any electrical work. This helps minimize mistakes and provides a safer installation.

- Electrical work requires specialized knowledge and skills for a safe and reliable electrical system. Instead of DIY work, hire a professional who can handle the job correctly and ensure compliance with safety standards.

- Faulty or damaged equipment can pose serious safety risks. All tools and equipment should be inspected to ensure they are in good working condition.

- Assess the work area for potential hazards. Keep an eye out for water sources, flammable materials, or other dangers compromising safety. Take appropriate measures to mitigate risks and create a safe environment

- Always wear the necessary safety gear when working with electricity. This includes insulated gloves, safety glasses, ear protection, and appropriate footwear.

- After completing electrical installations or repairs, test the work to ensure it has been done correctly. Use appropriate testing equipment, such as voltage testers or multimeters, to verify that circuits are properly wired and functioning as intended.

Common Issues of 150 Amp Service and Troubleshooting Guide

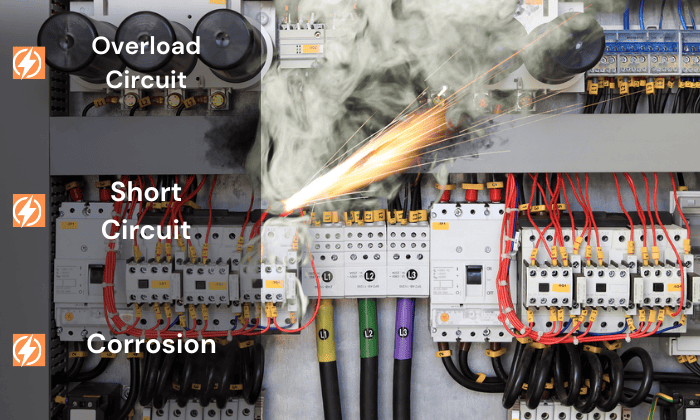

- Overload Circuit

One common issue with a 150-amp service is overloading the electrical circuits. It typically trips the breaker when the total electrical demand exceeds the capacity of the service.

To troubleshoot an overload issue, identify high-demand appliances or devices and redistribute the load across different circuits. Consider upgrading to a higher ampacity service if necessary.

- Short Circuit

Another issue is a short circuit, which occurs when a hot wire comes into direct contact with a neutral or ground wire. This can result in a sudden loss of power, tripped breakers, or blown fuses.

To troubleshoot a short circuit, locate the affected circuit, identify and repair the damaged wiring or faulty connections, and ensure proper insulation and separation of wires.

- Corrosion

Corrosion can occur on electrical connections, especially in humid or moist environments. It can lead to poor conductivity, increased resistance, and potential electrical failures.

To troubleshoot corrosion issues, inspect electrical connections for signs of corrosion such as discoloration or rust. Clean the affected areas using appropriate methods and materials, and consider applying corrosion inhibitors or dielectric grease for added protection.

Read next: What Size Wire for 100 Amp Service 300 Ft Away

Frequently Asked Questions

What are the Potential Dangers of Using the Wrong Wire Size?

Overheating, voltage loss, increased resistance, and potential fire dangers can all result from using the wrong size of wire. It can also harm equipment and affect the overall safety and efficiency of the electrical system.

Can I Mix Copper and Alum Wires in My 150 Amp Service?

Mixing copper and alum wire in a 150-amp service panel is possible. However, proper techniques should be used as they may involve fire hazards and safety risks. In this case, consult a professional for safe and reliable installations.

Can I Use a Smaller Wire Size for a Short Distance?

Wire size should be chosen based on ampacity and voltage drop estimates, regardless of distance. Even in short distances, the minimum wire size must meet current-carrying requirements to avoid excessive heat buildup and assure proper electrical performance.

How Much Does It Cost to Install and Upgrade the Service?

The cost of establishing or upgrading a residential service might vary depending on several factors, including the project’s complexity, location, labor rates, and supplies needed. In most cases, it is usually worth an average of $1300.

Getting quotations from licensed electricians in your local area is recommended to get an accurate estimate that considers your individual situation.

How to Tell that I Have 150 Amp Service?

You can check your electrical panel to determine if you have a 150-amp service. The main panel breaker usually indicates your electrical system’s service size or capacity.

Conclusion

Knowing what size wire for 150 amp service is essential for the safety and reliability of an electrical system. However, to determine the recommended wire size specifically for your application, you need to consider some factors such as length, material, percentage of voltage drop, and system voltage.

It’s important to prioritize safety considerations and follow best practices, including proper wire insulation and protection as well as compliance with relevant codes and regulations. Seeking expert advice when necessary is strongly advised to secure the best possible results.

I am Edwin Jones, in charge of designing content for Galvinpower. I aspire to use my experiences in marketing to create reliable and necessary information to help our readers. It has been fun to work with Andrew and apply his incredible knowledge to our content.